Subpart E Personal Protective and Life Saving Equipment

1926.95

Criteria for personal protective equipment.

1926.96

Occupational foot protection.

1926.97

(Reserved)

1926.98

(Reserved)

1926.99

(Reserved)

1926.100

Head protection

1926.101 Hearing

protection

1926.102

Eye and face protection

1926.103

Respiratory protection

1926.104

Safety belts, lifelines, and lanyards

1926.105

Safety nets

1926.106

Working over or near water.

1926.107

Definitions applicable to this subpart.

Authority: Sec. 107,

Contract Work Hours and Safety Standards Act (Construction Safety Act) (40

U.S.C. 333); Secs. 4, 6, 8, Occupational Safety and Health Act of 1970 (29

U.S.C. 653, 655, 657); Secretary of Labor's Order 12-71 (36 FR 8754), 8-76 (41

FR 25059), 9-83 (48 FR 35736), or 1-90 (55 FR 9033), or 6-96 (62 FR 111),

5-2002 (67 FR 65008), or 5-2007 (72 FR 31160) as applicable; and 29 CFR part

11.

1926.95 Criteria for personal

protective equipment.

(a) Application.

Protective equipment, including personal protective equipment for eyes, face,

head, and extremities, protective clothing, respiratory devices, and protective

shields and barriers, shall be provided, used, and maintained in a sanitary and

reliable condition wherever it is necessary by reason of hazards of processes

or environment, chemical hazards, radiological hazards, or mechanical irritants

encountered in a manner capable of causing injury or impairment in the function

of any part of the body through absorption, inhalation or physical contact. STD

1-1.13 STD 1-6.1

(b) Employee-owned

equipment. Where employees provide their own protective equipment, the employer

shall be responsible to assure its adequacy, including proper maintenance, and

sanitation of such equipment.

(c) Design.

All personal protective equipment shall be of safe design and construction for

the work to be performed.

(d) Payment for protective equipment.

(1) Except as provided by paragraphs

(d)(2) through (d)(6) of this section, the protective equipment, including

personal protective equipment (PPE), used to comply with this part, shall be

provided by the employer at no cost to employees.

(2) The employer is not required to

pay for non-specialty safety-toe protective footwear (including steel-toe shoes

or steel-toe boots) and non-specialty prescription safety eyewear, provided

that the employer permits such items to be worn off the job-site.

(3) When the employer provides

metatarsal guards and allows the employee, at his or her request, to use shoes

or boots with built-in metatarsal protection, the employer is not required to

reimburse the employee for the shoes or boots.

(4) The employer is not required to

pay for:

(i) Everyday clothing,

such as long-sleeve shirts, long pants, street shoes, and normal work boots; or

(ii) Ordinary clothing,

skin creams, or other items, used solely for protection from weather, such as

winter coats, jackets, gloves, parkas, rubber boots, hats, raincoats, ordinary

sunglasses, and sunscreen.

(5) The employer must pay for

replacement PPE, except when the employee has lost or intentionally damaged the

PPE.

(6) Where an employee provides

adequate protective equipment he or she owns pursuant to paragraph (b) of this

section, the employer may allow the employee to use it and is not required to

reimburse the employee for that equipment. The employer shall not require an

employee to provide or pay for his or her own PPE, unless the PPE is excepted

by paragraphs (d)(2) through (d)(5) of this section.

(7) This section shall become effective

on February 13, 2008. Employers must implement the PPE payment requirements no

later than May 15, 2008.

Note to Sec. 1926.95(d): When the provisions of

another OSHA standard specify whether or not the employer must pay for specific

equipment, the payment provisions of that standard shall prevail.

1926.96

Occupational foot protection.

Safety-toe footwear

for employees shall meet the requirements and specifications in American

National Standard for Men's Safety-Toe Footwear, Z41.1-1967.

1926.97 Reserved.

1926.98 Reserved.

1926.99 Reserved.

1926.100 Head

Protection

(a) Employees

working in areas where there is a possible danger of head injury from impact,

or from falling or flying objects, or from electrical shock and burns, shall be

protected by protective helmets.

(b) Helmets for the

protection of employees against impact and penetration of falling and flying

objects shall meet the specifications contained in American National Standards

Institute, Z89.1-1969, Safety Requirements for Industrial Head Protection.

(c) Helmets

for the head protection of employees exposed to high voltage electrical shock

and burns shall meet the specifications contained in American National

Standards Institute, Z89.2-1971.

1926.101 Hearing

protection

(a) Wherever it is

not feasible to reduce the noise levels or duration of exposures to those

specified in Table D-2, Permissible Noise Exposures, in 1926.52, ear protective

devices shall be provided and used.

(b) Ear protective

devices inserted in the ear shall be fitted or determined individually by

competent persons.

(c) Plain cotton

is not an acceptable protective device.

1926.102 Eye and

face protection

(a) General

(1)

Employees shall be provided with eye and face protection equipment when

machines or operations present potential eye or face injury from physical,

chemical, or radiation agents.

(2) Eye

and face protection equipment required by this Part shall meet the requirements

specified in American National Standards Institute, Z87.1-1968, Practice for

Occupational and Educational Eye and Face Protection.

(3) Employees

whose vision requires the use of corrective lenses in spectacles, when required

by this regulation to wear eye protection, shall be protected by goggles or

spectacles of one of the following types:

(i)

Spectacles whose protective lenses provide optical correction;

(ii)

Goggles that can be worn over corrective spectacles without disturbing the

adjustment of the spectacles;

(iii)

Goggles that incorporate corrective lenses mounted behind the protective

lenses.

(4) Face

and eye protection equipment shall be kept clean and in good repair. The use of

this type equipment with structural or optical defects shall be prohibited.

(5) Table

E-1 shall be used as a guide in the selection of face and eye protection for

the hazards and operations noted.

TABLE E-1 - Eye and

Face Protector Selection Guide

1. GOGGLES, Flexible Fitting

- Regular Ventilation

2. GOGGLES, Flexible Fitting

- Hooded Ventilation

3. GOGGLES, Cushioned Fitting

- Rigid Body

4. SPECTACLES, Metal Frame,

with Sideshields (1)

5. SPECTACLES, Plastic Frame -

with Sideshields (1)

6. SPECTACLES, Metal-Plastic

Frame - with Sideshields (1)

7. WELDING GOGGLES, Eyecup

Type - Tinted Lenses (2)

7A. CHIPPING GOGGLES, Eyecup

Type - Clear Safety Lenses

8. WELDING GOGGLES, Coversepc

Type - Tinted Lenses (2)

8A. CHIPPING GOGGLES,

Coverspec Type - Clear Safety Lenses

9. WELDING GOGGLES, Coverspec

Type - Tinted Plate Lens (2)

10. FACE SHIELD (Available

with Plastic or Mesh Window)

11. WELDING HELMETS (2)

Footnote(1)

Non-side shield spectacles are available for limited hazard use requiring only

frontal protection.

Footnote(2)

See Table E-2, in paragraph (b) of this section, Filter Lens Shade Numbers for

Protection Against Radiant Energy.

Applications

_______________________________________________________________________

| |

| | Recommended protectors:

Operation |

Hazards | Bold type numbers signify

| | preferred protection

__________________|________________________|____________________________

| |

Acetylene-Burning,| Sparks, harmful rays, | 7, 8, 9.

Acetylene-Cutting,| molten

metal, flying |

Acetylene-Welding |

particles............ |

__________________|________________________|____________________________

| |

Chemical Handling | Splash,

acid burns, | 2, 10 (For sever exposure

|

fumes................ | add 10 over 2).

__________________|________________________|____________________________

| |

Chipping..........| Flying

particles.......| 1, 3, 4, 5, 6, 7A, 8A.

__________________|________________________|____________________________

| |

Electric (arc) | Sparks, intense rays, | 9, 11,(11 in combination

welding...........| molten

metal..........| with 4, 5, 6, in tinted

| | lenses advisable)

__________________|________________________|____________________________

| |

Furnace operations| Glare,

heat, molten | 7, 8, 9 (For severe

|

metal.................| exposure add 10).

__________________|________________________|____________________________

| |

Grinding-Light....| Flying

particles.......| 1, 3, 4, 5, 6, 10.

__________________|________________________|____________________________

| |

Grinding-Heavy....| Flying

particles.......| 1, 3, 7A, 8A (For severe

| | exposure add 10)

__________________|________________________|____________________________

| |

Laboratory........| Chemical

splash, | 2 (10 when in combination

| glass

breakage........| with 4, 5, 6).

__________________|________________________|____________________________

| |

Machining.........| Flying

particles.......| 1, 3, 4, 5, 6, 10.

__________________|________________________|____________________________

| |

Molten metals.....| Heat,

glare, sparks, | 7, 8, (10 in combination

|

splash................| with 4, 5, 6, in tinted lenses)

__________________|________________________|____________________________

| |

Spot welding......| Flying

particles, | 1, 3, 4, 5, 6, 10

|

sparks................|

__________________|________________________|____________________________

(6)

Protectors shall meet the following minimum requirements:

(i)

They shall provide adequate protection against the particular hazards for which

they are designed.

(ii)

They shall be reasonably comfortable when worn under the designated conditions.

(iii)

They shall fit snugly and shall not unduly interfere with the movements of the

wearer.

(iv) They shall

be durable.

(v) They shall

be capable of being disinfected.

(vi)

They shall be easily cleanable.

(7) Every

protector shall be distinctly marked to facilitate identification only of the

manufacturer.

(8) When

limitations or precautions are indicated by the manufacturer, they shall be

transmitted to the user and care taken to see that such limitations and

precautions are strictly observed.

(b) Protection

against radiant energy

(1)

Selection of shade numbers for welding filter. Table E-2 shall be used as a

guide for the selection of the proper shade numbers of filter lenses or plates

used in welding. Shades more dense than those listed may be used to suit the

individual's needs.

TABLE

E-2 - FILTER LENS SHADE NUMBERS FOR PROTECTION AGAINST

RADIANT ENERGY

__________________________________________________________________

|

| Shade

Welding

operation | number

_______________________________________________________|__________

|

Shielded metal-arc welding

1/16-, 3/32-, 1/8-, 5/32- |

inch diameter electrodes..............................|

10

Gas-shielded arc welding

(nonferrous) 1/16-, 3/32-, |

1/8-, 5/32-inch diameter

electrodes...................| 11

Gas-shielded arc welding

(ferrous) 1/16-, 3/32-, 1/8-, |

5/32-inch diameter

electrodes.........................| 12

Shielded metal-arc welding

3/16-, 7/32-, 1/4-inch |

diameter

electrodes...................................| 12

5/16-, 3/8-inch diameter

electrodes....................| 14

Atomic hydrogen

welding................................| 10-14

Carbon-arc

welding.....................................| 14

Soldering..............................................|

2

Torch

brazing..........................................| 3 or 4

Light cutting, up to 1

inch............................| 3 or 4

Medium cutting, 1 inch to 6

inches.....................| 4 or 5

Heavy cutting, over 6

inches...........................| 5 or 6

Gas welding (light), up to

1/8-inch....................| 4 or 5

Gas welding (medium), 1/8-inch

to 1/2-inch.............| 5 or 6

Gas welding (heavy), over

1/2-inch.....................| 6 or 8

_______________________________________________________|__________

(2) Laser

protection.

(i)

Employees whose occupation or assignment requires exposure to laser beams shall

be furnished suitable laser safety goggles which will protect for the specific

wavelength of the laser and be of optical density (O.D.) adequate for the

energy involved. Table E-3 lists the maximum power or energy density for which

adequate protection is afforded by glasses of optical densities from 5 through

8.

TABLE E-3 - SELECTING LASER SAFETY GLASS

___________________________________________________________

|

Intensity, CW

| Attenuation

maximum power

|_______________________________________

density

| |

(watts/cm(2) | Optical

density | Attenuation

|

(O.D.) | factor

__________________|____________________|__________________

| |

10(-2)

| 5 | 10(5)

10(-1)

| 6 | 10(6)

1.0

| 7 | 10(7)

10.0 |

8 | 10(8)

__________________|____________________|__________________

Output levels falling between

lines in this table shall require the higher optical density.

(ii)

All protective goggles shall bear a label identifying the following data:

(a)

The laser wavelengths for which use is intended;

(b)

The optical density of those wavelengths;

(c)

The visible light transmission.

1926.103 Respiratory

Protection

Note: The

requirements applicable to construction work under this section are identical

to those set forth at 29 CFR 1910.134 of this chapter.

1926.104 Safety

belts, lifelines, and lanyards

(a) Lifelines,

safety belts, and lanyards shall be used only for employee safeguarding. Any

lifeline, safety belt, or lanyard actually subjected to in-service loading, as

distinguished from static load testing, shall be immediately removed from

service and shall not be used again for employee safeguarding.

(b) Lifelines shall

be secured above the point of operation to an anchorage or structural member

capable of supporting a minimum dead weight of 5,400 pounds.

(c) Lifelines used on

rock-scaling operations, or in areas where the lifeline may be subjected to

cutting or abrasion, shall be a minimum of 7/8-inch wire core manila rope. For

all other lifeline applications, a minimum of 3/4-inch manila or equivalent,

with a minimum breaking strength of 5,400 pounds, shall be used.

(d) Safety belt

lanyard shall be a minimum of 1/2-inch nylon, or equivalent, with a maximum

length to provide for a fall of no greater than 6 feet. The rope shall have a

nominal breaking strength of 5,400 pounds.

(e) All safety belt

and lanyard hardware shall be drop forged or pressed steel, cadmium plated in

accordance with type 1, Class B plating specified in Federal Specification

QQ-P-416. Surface shall be smooth and free of sharp edges.

(f) All safety

belt and lanyard hardware, except rivets, shall be capable of withstanding a

tensile loading of 4,000 pounds without cracking, breaking, or taking a permanent

deformation.

1926.105 Safety

nets

(a) Safety nets shall

be provided when workplaces are more than 25 feet above the ground or water

surface, or other surfaces where the use of ladders, scaffolds, catch

platforms, temporary floors, safety lines, or safety belts is impractical.

(b) Where safety net

protection is required by this part, operations shall not be undertaken until

the net is in place and has been tested.

(c)

(1) Nets

shall extend 8 feet beyond the edge of the work surface where employees are

exposed and shall be installed as close under the work surface as practical but

in no case more than 25 feet below such work surface. Nets shall be hung with

sufficient clearance to prevent user's contact with the surfaces or structures

below. Such clearances shall be determined by impact load testing.

(2) It is

intended that only one level of nets be required for bridge construction.

(d) The mesh size of

nets shall not exceed 6 inches by 6 inches. All new nets shall meet accepted

performance standards of 17,500 foot-pounds minimum impact resistance as

determined and certified by the manufacturers, and shall bear a label of proof

test. Edge ropes shall provide a minimum breaking strength of 5,000 pounds.

(e) Forged steel

safety hooks or shackles shall be used to fasten the net to its supports.

(f) Connections

between net panels shall develop the full strength of the net.

1926.106 Working over or near water.

(a) Employees working over or near water, where

the danger of drowning exists, shall be provided with U.S. Coast Guard-approved

life jacket or buoyant work vests.

(b) Prior to and after each use, the buoyant

work vests or life preservers shall be inspected for defects which would alter

their strength or buoyancy. Defective units shall not be used.

(c) Ring buoys with at least 90 feet of line

shall be provided and readily available for emergency rescue operations.

Distance between ring buoys shall not exceed 200 feet.

(d) At least one lifesaving skiff shall be

immediately available at locations where employees are working over or adjacent

to water.

1926.107 Definitions applicable to this

subpart.

(a) "Contaminant" means any material

which by reason of its action upon, within, or to a person is likely to cause

physical harm.

(b) "Lanyard" means a rope, suitable

for supporting one person. One end is fastened to a safety belt or harness and

the other end is secured to a substantial object or a safety line.

(c) "Lifeline" means a rope, suitable

for supporting one person, to which a lanyard or safety belt (or harness) is

attached.

(d) "O.D." means optical density and

refers to the light refractive characteristics of a lens.

(e) "Radiant energy" means energy that

travels outward in all directions from its sources.

(f) "Safetybelt" means a device,

usually worn around the waist which, by reason of its attachment to a lanyard

and lifeline or a structure, will prevent a worker from falling.

Subpart I ‑

Personal Protective Equipment

1910.132 General

requirements.

1910.133 Eye

and face protection.

1910.134 Respiratory

protection.

1910.135 Head

protection.

1910.136 Foot

protection.

1910.137 Electrical

protective equipment.

1910.138 Hand

Protection

Appendix A References

for further information (Non‑mandatory)

Appendix B Non‑mandatory

Compliance Guidelines for Hazard Assessment and Personal Protective Equipment

Selection

SUBPART I ‑‑ Personal

Protective Equipment

AUTHORITY: Sections 4, 6, and 8

of the Occupational Safety and Health Act of 1970 (29 U.S.C. 653, 655, and

657); Secretary of Labor's Order No. 12-71 (36 FR 8754), 8-76 (41 FR 25059),

9-83 (48 FR 35736), 1-90 (55 FR 9033), 6-96 (62 FR 111), 3-2000 (65 FR 50017),

5-2002 (67 FR 65008), or 5-2007 (72 FR 31160), as applicable, and 29 CFR Part

1911.

1910.132 General requirements.

(a) Application.

Protective equipment, including personal protective equipment for eyes, face,

head, and extremities, protective clothing, respiratory devices, and protective

shields and barriers, shall be provided, used, and maintained in a sanitary and

reliable condition wherever it is necessary by reason of hazards of processes

or environment, chemical hazards, radiological hazards, or mechanical irritants

encountered in a manner capable of causing injury or impairment in the function

of any part of the body through absorption, inhalation or physical contact.

STD 1‑1.13 STD 1‑6.1

STEP

(b) Employee‑owned

equipment. Where employees provide their own protective equipment, the employer

shall be responsible to assure its adequacy, including proper maintenance, and

sanitation of such equipment.

(c) Design. All

personal protective equipment shall be of safe design and construction for the

work to be performed.

(d) Hazard assessment

and equipment selection.

(1)

The employer shall assess the workplace to determine if hazards are present, or

are likely to be present, which necessitate the use of personal protective

equipment (PPE). If such hazards are present, or likely to be present, the

employer shall:

(i)

Select, and have each affected employee use, the types of PPE that will protect

the affected employee from the hazards identified in the hazard assessment;

(ii)

Communicate selection decisions to each affected employee; and,

(iii)

Select PPE that properly fits each affected employee.

Note: Non‑mandatory

Appendix B contains an example of procedures that would comply with the

requirement for a hazard assessment.

(2)

The employer shall verify that the required workplace hazard assessment has

been performed through a written certification that identifies the workplace

evaluated; the person certifying that the evaluation has been performed; the

date(s) of the hazard assessment; and, which identifies the document as a

certification of hazard assessment.

(e) Defective and

damaged equipment. Defective or damaged personal protective equipment shall not

be used.

(f) Training.

(1)

The employer shall provide training to each employee who is required by this

section to use PPE. Each such employee shall be trained to know at least the

following:

(i)

When PPE is necessary;

(ii)

What PPE is necessary;

(iii)

How to properly don, doff, adjust, and wear PPE;

(iv)

The limitations of the PPE; and,

(v)

The proper care, maintenance, useful life and disposal of the PPE.

(2)

Each affected employee shall demonstrate an understanding of the training

specified in paragraph (f)(1) of this section, and the ability to use PPE

properly, before being allowed to perform work requiring the use of PPE.

(3)

When the employer has reason to believe that any affected employee who has

already been trained does not have the understanding and skill required by

paragraph (f)(2) of this section, the employer shall retrain each such

employee. Circumstances where retraining is required include, but are not

limited to, situations where:

(i)

Changes in the workplace render previous training obsolete; or

(ii)

Changes in the types of PPE to be used render previous training obsolete; or

(iii)

Inadequacies in an affected employee's knowledge or use of assigned PPE indicate

that the employee has not retained the requisite understanding or skill.

(4)

The employer shall verify that each affected employee has received and

understood the required training through a written certification that contains

the name of each employee trained, the date(s) of training, and that identifies

the subject of the certification.

(g) Paragraphs (d)

and (f) of this section apply only to 1910.133, 1910.135, 1910.136, and

1910.138. Paragraphs (d) and (f) of this section do not apply to 1910.134 and

1910.137.

(h) Payment for protective

equipment.

(1) Except as provided by

paragraphs (h)(2) through (h)(6) of this section, the protective equipment,

including personal protective equipment (PPE), used to comply with this part,

shall be provided by the employer at no cost to employees.

(2) The employer is not required

to pay for non-specialty safety-toe protective footwear (including steel-toe

shoes or steel-toe boots) and non-specialty prescription safety eyewear,

provided that the employer permits such items to be worn off the job-site.

(3) When the employer provides

metatarsal guards and allows the employee, at his or her request, to use shoes

or boots with built-in metatarsal protection, the employer is not required to

reimburse the employee for the shoes or boots.

(4) The employer is not required

to pay for:

(i) The logging boots required by

29 CFR 1910.266(d)(1)(v);

(ii) Everyday clothing, such as

long-sleeve shirts, long pants, street shoes, and normal work boots; or

(iii) Ordinary clothing, skin

creams, or other items, used solely for protection from weather, such as winter

coats, jackets, gloves, parkas, rubber boots, hats, raincoats, ordinary

sunglasses, and sunscreen.

(5) The employer must

pay for replacement PPE, except when the employee has lost or intentionally

damaged the PPE.

(6) Where an employee

provides adequate protective equipment he or she owns pursuant to paragraph (b)

of this section, the employer may allow the employee to use it and is not

required to reimburse the employee for that equipment. The employer shall not

require an employee to provide or pay for his or her own PPE, unless the PPE is

excepted by paragraphs (h)(2) through (h)(5) of this section.

(7) This paragraph (h)

shall become effective on February 13, 2008. Employers must implement the PPE

payment requirements no later than May 15, 2008.

Note to Sec. 1910.132(h): When the provisions of another

OSHA standard specify whether or not the employer must pay for specific

equipment, the payment provisions of that standard shall prevail.

1910.133 Eye and face

protection.

(a) General

requirements.

(1)

The employer shall ensure that each affected employee uses appropriate eye or

face protection when exposed to eye or face hazards from flying particles,

molten metal, liquid chemicals, acids or caustic liquids, chemical gases or

vapors, or potentially injurious light radiation.

(2)

The employer shall ensure that each affected employee uses eye protection that

provides side protection when there is a hazard from flying objects. Detachable

side protectors (e.g. clip‑on or slide‑on side shields) meeting the

pertinent requirements of this section are acceptable.

(3)

The employer shall ensure that each affected employee who wears prescription

lenses while engaged in operations that involve eye hazards wears eye

protection that incorporates the prescription in its design, or wears eye

protection that can be worn over the prescription lenses without disturbing the

proper position of the prescription lenses or the protective lenses.

(4)

Eye and face PPE shall be distinctly marked to facilitate identification of the

manufacturer.

(5)

The employer shall ensure that each affected employee uses equipment with

filter lenses that have a shade number appropriate for the work being performed

for protection from injurious light radiation. The following is a listing of

appropriate shade numbers for various operations.

Filter Lenses for Protection Against Radiant Energy

____________________________________________________________________

Minimum(*)

Operations Electrode Size

1/32 in. Arc Current Protective

Shade

_____________________________________________________________________

Shielded metal

arc welding Less than 3

......... Less than 60 ... 7

3-5

................. 60-160 ......... 8

5-8

................. 160-250 ........ 10

More than 8

......... 250-550 ........ 11

_____________________________________________________________________

Gas metal arc

welding and

flux cored

arc

welding less than 60 ... 7

60-160 ......... 10

160-250 ........ 10

250-500 ........ 10

_____________________________________________________________________

Gas Tungsten

arc

welding less than 50 ... 8

50-150 ......... 8

150-500

........ 10

_____________________________________________________________________

Air carbon (Light)

............. less than 500 .. 10

Arc cutting (Heavy)

............. 500-1000 ....... 11

_____________________________________________________________________

Plasma arc

welding less than 20 ... 6

20-100 ......... 8

100-400 ........ 10

400-800

........ 11

_____________________________________________________________________

Plasma arc (light)(**)

......... less than 300 .. 8

cutting (medium)(**)

........ 300-400 ........ 9

(heavy)(**)

......... 400-800 ........ 10

_____________________________________________________________________

Torch

brazing ................ 3

Torch

soldering ................ 2

Carbon arc

welding ................ 14

_____________________________________________________________________

Filter Lenses for

Protection Against Radiant Energy

_____________________________________________________________________

Minimum(*)

Operations Plate

thickness-inches Plate thickness-mm Protective

Shade

_____________________________________________________________________

Gas Welding:

Light Under 1/8

............ Under 3.2 ......... 4

Medium 1/8 to 1/2

........... 3.2 to 12.7 ....... 5

Heavy Over 1/2

............. Over 12.7 ......... 6

_____________________________________________________________________

Oxygen cutting:

Light Under 1

.............. Under 25 .......... 3

Medium 1 to 6

............... 25 to 150 ......... 4

Heavy Over 6

............... Over 150 .......... 5

______________________________________________________________________

Footnote(*) As a rule of

thumb, start with a shade that is too dark

to see the weld zone. Then go

to a lighter shade which gives

sufficient view of the weld

zone without going below the minimum. In

oxyfuel gas welding or cutting

where the torch produces a high yellow

light, it is desirable to use

a filter lens that absorbs the yellow

or sodium line in the visible

light of the (spectrum) operation.

Footnote(**) These values

apply where the actual arc is clearly

seen. Experience has shown

that lighter filters may be used when the

arc is hidden by the

workpiece.

(b)

Criteria for protective eye and face devices.

(1) Protective eye and face devices

purchased after July 5, 1994 shall comply with ANSI Z87.1‑1989,

``American National Standard Practice for Occupational and Educational Eye and

Face Protection,'' which is incorporated by reference as specified in 1910.6.,

or shall be demonstrated by the employer to be equally effective.

(2) Eye and face protective devices

purchased before July 5, 1994 shall comply with the ANSI ``USA standard for Occupational and Educational Eye and Face Protection,'' Z87.1‑1968, which is

incorporated by reference as specified in 1910.6, or shall be demonstrated by

the employer to be equally effective.

1910.134 Respiratory

Protection. This section applies to General Industry (part 1910),

Shipyards (part 1915), Marine Terminals (part 1917), Long shoring (part 1918),

and Construction (part 1926).

(a) Permissible

practice.

(1) In the

control of those occupational diseases caused by breathing air contaminated

with harmful dusts, fogs, fumes, mists, gases, smokes, sprays, or vapors, the

primary objective shall be to prevent atmospheric contamination. This shall be

accomplished as far as feasible by accepted engineering control measures (for

example, enclosure or confinement of the operation, general and local

ventilation, and substitution of less toxic materials). When effective

engineering controls are not feasible, or while they are being instituted,

appropriate respirators shall be used pursuant to this section.

(2) Respirators

shall be provided by the employer when such equipment is necessary to protect

the health of the employee. The employer shall provide the respirators which

are applicable and suitable for the purpose intended. The employer shall be

responsible for the establishment and maintenance of a respiratory protection

program which shall include the requirements outlined in paragraph (c) of this

section.

(b)

Definitions. The following definitions are important terms used in the

respiratory protection standard in this section.

"Air‑purifying

respirator" means a respirator with an air‑purifying filter,

cartridge, or canister that removes specific air contaminants by passing

ambient air through the air‑purifying element.

“Assigned

protection factor (APF)“means the workplace level of respiratory protection

that a respirator or class of respirators is expected to provide to employees

when the employer implements a continuing, effective respiratory protection

program as specified by this section.

"Atmosphere‑supplying

respirator" means a respirator that supplies the respirator

user with breathing air from a source independent of the

ambient atmosphere, and includes supplied‑air respirators (SARs) and

self‑contained breathing apparatus (SCBA) units.

"Canister or cartridge" means a

container with a filter, sorbent, or catalyst, or combination of these items,

which removes specific contaminants from the air passed through the container.

"Demand

respirator" means an atmosphere‑supplying respirator that admits

breathing air to the facepiece only when a negative pressure is created inside

the facepiece by inhalation.

"Emergency

situation" means any occurrence such as, but not limited to, equipment

failure, rupture of containers, or failure of control equipment that may or

does result in an uncontrolled significant release of an airborne contaminant.

"Employee

exposure" means exposure to a concentration of an airborne contaminant

that would occur if the employee were not using respiratory protection.

"End‑of‑service‑life

indicator (ESLI)" means a system that warns the respirator user

of the approach of the end of

adequate respiratory protection, for example, that the sorbent is approaching

saturation or is no longer effective.

"Escape‑only

respirator" means a respirator intended to be used only for emergency

exit.

"Filter

or air purifying element" means a component used in respirators to

remove

solid or liquid aerosols from the

inspired air.

"Filtering

facepiece (dust mask)" means a negative pressure particulate

respirator

with a filter as an integral part

of the facepiece or with the entire facepiece

composed of the filtering medium.

"Fit factor"

means a quantitative estimate of the fit of a particular respirator to a

specific individual, and

typically estimates the ratio of the concentration of a substance in ambient

air to its concentration inside the respirator when worn.

"Fit

test" means the use of a protocol to qualitatively or quantitatively

evaluate the fit of a respirator on an individual. (See also Qualitative fit

test QLFT and Quantitative fit test QNFT.)

"Helmet"

means a rigid respiratory inlet covering that also provides head protection

against impact and penetration.

"High

efficiency particulate air (HEPA) filter" means a filter that is at

least 99.97% efficient in removing monodisperse particles of 0.3 micrometers in

diameter. The equivalent NIOSH 42 CFR 84 particulate filters are the N100,

R100, and P100 filters.

"Hood"

means a respiratory inlet covering that completely covers the head and neck and

may also cover portions of the shoulders and torso.

"Immediately

dangerous to life or health (IDLH)" means an atmosphere that poses an

immediate threat to life, would

cause irreversible adverse health effects, or would impair an individual's

ability to escape from a dangerous atmosphere.

"Interior

structural firefighting" means the physical activity of fire

suppression, rescue or both, inside of buildings or enclosed structures which

are involved in a fire situation beyond the incipient stage. (See 29 CFR

1910.155)

"Loose‑fitting

facepiece" means a respiratory inlet covering that is designed to form

a partial seal with the face.

“Maximum use

concentration (MUC)” means the maximum atmospheric concentration of a

hazardous substance from which an employee can be expected to be protected when

wearing a respirator, and is determined by the assigned protection factor of

the respirator or class of respirators and the exposure limit of the hazardous

substance. The MUC can be determined mathematically by multiplying the assigned

protection factor specified for a respirator by the required OSHA permissible

exposure limit, short-term exposure limit, or ceiling limit. When no OSHA

exposure limit is available for a hazardous substance, an employer must

determine an MUC on the basis of relevant available information and informed

professional judgment.

"Negative

pressure respirator (tight fitting)" means a respirator in which the

air pressure inside the facepiece is negative during inhalation with respect to

the ambient air pressure outside the respirator.

"Oxygen

deficient atmosphere means" an atmosphere with an oxygen content below

19.5% by volume.

"Physician

or other licensed health care professional (PLHCP)" means an

individual whose legally permitted scope of practice (i.e., license,

registration, or certification) allows him or her to independently provide, or

be delegated the responsibility to provide, some or all of the health care

services required by paragraph (e) of this section.

"Positive

pressure respirator" means a respirator in which the pressure inside

the respiratory inlet covering exceeds the ambient air pressure outside the

respirator.

"Powered

air‑purifying respirator (PAPR)" means an air‑purifying

respirator that uses a blower to force the ambient air through air‑purifying

elements to the inlet covering.

"Pressure

demand respirator" means a positive pressure atmosphere‑supplying

respirator that admits breathing air to the facepiece when the positive

pressure is reduced inside the facepiece by inhalation.

"Qualitative

fit test (QLFT)" means a pass/fail fit test to assess the adequacy of

respirator fit that relies on the individual's response to the test agent.

"Quantitative

fit test (QNFT)" means an assessment of the adequacy of respirator fit

by numerically measuring the amount of leakage into the respirator.

"Respiratory

inlet covering" means that portion of a respirator that forms the

protective barrier between the user's respiratory tract and an air‑purifying

device or breathing air source, or both. It may be a facepiece, helmet, hood,

suit, or a mouthpiece respirator with nose clamp.

"Self‑contained

breathing apparatus (SCBA)" means an atmosphere‑supplying

respirator for which the breathing air source is designed to be carried by the

user.

"Service

life means" the period of time that a respirator, filter or sorbent,

or other respiratory equipment provides adequate protection to the wearer.

"Supplied‑air

respirator (SAR) or airline respirator" means an atmosphere‑supplying

respirator for which the source of breathing air is not designed to be carried

by the user.

"This

section" means this respiratory protection standard.

"Tight‑fitting

facepiece" means a respiratory inlet covering that forms a complete

seal with the face.

"User

seal check" means an action conducted by the respirator user to

determine if the respirator is properly seated to the face.

(c) Respiratory

protection program. This paragraph requires the employer to develop and implement

a written respiratory protection program with required worksite‑specific

procedures and elements for required respirator use. The program must be

administered by a suitably trained program administrator. In addition, certain

program elements may be required for voluntary use to prevent potential

hazards associated with the use of the respirator. The Small Entity Compliance

Guide contains criteria for the selection of a program administrator and a

sample program that meets the requirements of this paragraph. Copies of the

Small Entity Compliance Guide will be available on or about April 8, 1998 from

the Occupational Safety and Health Administration's Office of Publications, Room

N 3101, 200 Constitution Avenue, NW, Washington, DC, 20210 (202‑219‑4667).

(1)

In any workplace where respirators are necessary to protect the health of the

employee or whenever respirators are required by the employer, the employer

shall establish and

implement a written respiratory

protection program with worksite‑specific procedures. The program shall

be updated as necessary to reflect those changes in workplace conditions that

affect respirator use. The employer shall include in the program the following

provisions of this section, as applicable:

(i)

Procedures for selecting respirators for use in the workplace;

(ii) Medical

evaluations of employees required to use respirators;

(iii) Fit

testing procedures for tight‑fitting respirators;

(iv) Procedures

for proper use of respirators in routine and reasonably foreseeable emergency

situations;

(v) Procedures

and schedules for cleaning, disinfecting, storing, inspecting, repairing,

discarding, and otherwise maintaining respirators;

(vi) Procedures

to ensure adequate air quality, quantity, and flow of breathing air for

atmosphere‑supplying respirators;

(vii) Training

of employees in the respiratory hazards to which they are potentially exposed

during routine and emergency situations;

(viii) Training

of employees in the proper use of respirators, including putting on and

removing them, any limitations on their use, and their maintenance; and

(ix) Procedures

for regularly evaluating the effectiveness of the program.

(2) Where

respirator use is not required:

(i) An employer

may provide respirators at the request of employees or permit employees to use

their own respirators, if the employer determines that such respirator use will

not in itself create a hazard. If the employer determines that any voluntary

respirator use is permissible, the employer shall provide the respirator users

with the information contained in Appendix D to this section ("Information

for Employees Using Respirators When Not Required Under the Standard");

and

(ii) In

addition, the employer must establish and implement those elements of a written

respiratory protection program necessary to ensure that any employee using a

respirator voluntarily is medically able to use that respirator, and that the

respirator is cleaned, stored, and maintained so that its use does not present

a health hazard to the user. Exception: Employers are not required to include

in a written respiratory protection program those employees whose only use of

respirators involves the voluntary use of filtering facepieces (dust masks).

(3) The

employer shall designate a program administrator who is qualified by

appropriate training or experience that is commensurate with the complexity of

the program to administer or oversee the respiratory protection program and

conduct the required evaluations of program effectiveness.

(4) The

employer shall provide respirators, training, and medical evaluations at no

cost to the employee.

(d) Selection

of respirators. This paragraph requires the employer to evaluate respiratory hazard(s)

in the workplace, identify relevant workplace and user factors, and base

respirator selection on these factors. The paragraph also specifies

appropriately protective respirators for use in IDLH atmospheres, and limits

the selection and use of air‑purifying respirators.

(1) General

requirements.

(i) The

employer shall select and provide an appropriate respirator based on the

respiratory hazard(s) to which the worker is exposed and workplace and user

factors that affect respirator performance and reliability.

(ii) The

employer shall select a NIOSH‑certified respirator. The respirator shall

be used in compliance with the conditions of its certification.

(iii) The

employer shall identify and evaluate the respiratory hazard(s) in the

workplace; this evaluation shall include a reasonable estimate of employee

exposures to respiratory hazard(s) and an identification of the contaminant's

chemical state and physical form. Where the employer cannot identify or

reasonably estimate the employee exposure, the employer shall consider the

atmosphere to be IDLH.

(iv) The

employer shall select respirators from a sufficient number of respirator models

and sizes so that the respirator is acceptable to, and correctly fits, the

user.

(2)

Respirators for IDLH atmospheres.

(i) The

employer shall provide the following respirators for employee use in IDLH

atmospheres:

(A) A full

facepiece pressure demand SCBA certified by NIOSH for a minimum service life of

thirty minutes, or

(B) A

combination full facepiece pressure demand supplied‑air respirator (SAR)

with auxiliary self‑contained air supply.

(ii)

Respirators provided only for escape from IDLH atmospheres shall be NIOSH‑certified

for escape from the atmosphere in which they will be used.

(iii) All

oxygen‑deficient atmospheres shall be considered IDLH. Exception: If the

employer demonstrates that, under all foreseeable conditions, the oxygen

concentration can be maintained within the ranges specified in Table II of this

section (i.e., for the altitudes set out in the table), then any atmosphere‑supplying

respirator may be used.

(3)

Respirators for atmospheres that are not IDLH.

(i) The

employer shall provide a respirator that is adequate to protect the health of

the employee and ensure compliance with all other OSHA statutory and regulatory

requirements, under routine and reasonably foreseeable emergency situations.

(A) Assigned Protection Factors (APFs) Employers must use the assigned

protection factors listed in Table 1 to select a respirator that meets or

exceeds the required level of employee protection. When using a combination

respirator (e.g., airline respirators with an air-purifying filter), employers

must ensure that the assigned protection factor is appropriate to the mode of

operation in which the respirator is being used.

Table

1. -- Assigned Protection Factors5

|

Type of respirator1,

2

|

Quarter mask

|

Half mask

|

Full

facepiece

|

Helmet/

hood

|

Loose-fitting

facepiece

|

|

1. Air-Purifying Respirator

|

5

|

310

|

50

|

..............

|

..............

|

|

2. Powered Air-Purifying Respirator (PAPR)

|

..............

|

50

|

1,000

|

425/1,000

|

25

|

|

3. Supplied-Air Respirator (SAR) or Airline Respirator

• Demand mode

• Continuous flow mode

• Pressure-demand or other positive-pressure mode

|

..............

..............

..............

|

10

50

50

|

50

1,000

1,000

|

..............

425/1,000

..............

|

..............

25

..............

|

|

4. Self-Contained Breathing Apparatus (SCBA)

• Demand mode

• Pressure-demand or other positive-pressure mode (e.g.,

open/closed circuit)

|

..............

..............

|

10

..............

|

50

10,000

|

50

10,000

|

..............

..............

|

Notes:

1Employers may select respirators

assigned for use in higher workplace concentrations of a hazardous substance

for use at lower concentrations of that substance, or when required respirator

use is independent of concentration.

2The assigned protection factors in

Table 1 are only effective when the employer implements a continuing, effective

respirator program as required by this section (29 CFR 1910.134), including

training, fit testing, maintenance, and use requirements.

3This APF category includes

filtering facepieces, and half masks with elastomeric facepieces.

4The employer must have evidence

provided by the respirator manufacturer that testing of these respirators

demonstrates performance at a level of protection of 1,000 or greater to

receive an APF of 1,000. This level of performance can best be demonstrated by

performing a WPF or SWPF study or equivalent testing. Absent such testing, all

other PAPRs and SARs with helmets/hoods are to be treated as loose-fitting

facepiece respirators, and receive an APF of 25.

5These APFs do not apply to

respirators used solely for escape. For escape respirators used in association

with specific substances covered by 29 CFR 1910 subpart Z, employers must refer

to the appropriate substance-specific standards in that subpart. Escape

respirators for other IDLH atmospheres are specified by 29 CFR 1910.134

(d)(2)(ii).

(B) Maximum

Use Concentration (MUC)

(1)

The employer must select a respirator for employee use that maintains the

employee's exposure to the hazardous substance, when measured outside the

respirator, at or below the MUC.

(2)

Employers must not apply MUCs to conditions that are immediately dangerous to

life or health (IDLH); instead, they must use respirators listed for IDLH

conditions in paragraph (d)(2) of this standard.

(3)

When the calculated MUC exceeds the IDLH level for a hazardous substance, or

the performance limits of the cartridge or canister, then employers must set

the maximum MUC at that lower limit.

(ii) The

respirator selected shall be appropriate for the chemical state and physical

form of the contaminant.

(iii) For

protection against gases and vapors, the employer shall provide:

(A) An

atmosphere‑supplying respirator, or

(B) An air‑purifying

respirator, provided that:

(1) The

respirator is equipped with an end‑of‑service‑life indicator

(ESLI) certified by NIOSH for the contaminant; or

(2) If there is

no ESLI appropriate for conditions in the employer's workplace, the employer

implements a change schedule for canisters and cartridges that is based on

objective information or data that will ensure that canisters and cartridges

are changed before the end of their service life. The employer shall describe

in the respirator program the information and data relied upon and the basis

for the canister and cartridge change schedule and the basis for reliance on

the data.

(iv) For

protection against particulates, the employer shall provide:

(A) An

atmosphere‑supplying respirator; or

(B) An air‑purifying

respirator equipped with a filter certified by NIOSH under 30 CFR part 11 as a

high efficiency particulate air (HEPA) filter, or an air‑purifying

respirator equipped with a filter certified for particulates by NIOSH under 42

CFR part 84; or

(C) For

contaminants consisting primarily of particles with mass median aerodynamic

diameters (MMAD) of at least 2 micrometers, an air‑purifying respirator

equipped with any filter certified for particulates by NIOSH.

TABLE I. ‑‑ Assigned Protection Factors [Reserved]

TABLE II

|

Altitude (ft.)

|

Oxygen deficient Atmospheres (% 02)

for which the employer atmosphere-may rely on supplying respirators

|

|

Less than 3,0013,001-4,0004,001-5,0005,001-6,0006,001-7,0007,001-8,0001

|

16.0-19.516.4-19.517.1-19.517.8-19.518.5-19.519.3-19.5

|

1Above 8,000 feet the exception does

not apply. Oxygen-enriched breathing air must be supplied above 14,000 feet.

(e) Medical

evaluation. Using a respirator may place a physiological burden on employees

that varies with the type of respirator worn, the job and workplace conditions

in which the respirator is used, and the medical status of the employee.

Accordingly, this paragraph specifies the minimum requirements for medical

evaluation that employers must implement to determine the employee's ability to

use a respirator.

(1) General.

The employer shall provide a medical evaluation to determine the employee's

ability to use a respirator, before the employee is fit tested or required to

use the respirator in the workplace. The employer may discontinue an employee's

medical evaluations when the employee is no longer required to use a

respirator.

(2) Medical

evaluation procedures.

(i) The

employer shall identify a physician or other licensed health care professional

(PLHCP) to perform medical evaluations using a medical questionnaire or an

initial medical examination that obtains the same information as the medical

questionnaire.

(ii) The

medical evaluation shall obtain the information requested by the questionnaire

in Sections 1 and 2, Part A of Appendix C of this section.

(3) Follow‑up

medical examination.

(i) The

employer shall ensure that a follow‑up medical examination is provided

for an employee who gives a positive response to any question among questions 1

through 8 in Section 2, Part A of Appendix C or whose initial medical

examination demonstrates the need for a follow‑up medical examination.

(ii) The follow‑up

medical examination shall include any medical tests, consultations, or

diagnostic procedures that the PLHCP deems necessary to make a final

determination.

(4)

Administration of the medical questionnaire and examinations.

(i) The medical

questionnaire and examinations shall be administered confidentially during the

employee's normal working hours or at a time and place convenient to the

employee. The medical questionnaire shall be administered in a manner that

ensures that the employee understands its content.

(ii) The

employer shall provide the employee with an opportunity to discuss the

questionnaire and examination results with the PLHCP.

(5)

Supplemental information for the PLHCP.

(i) The

following information must be provided to the PLHCP before the PLHCP makes a recommendation

concerning an employee's ability to use a respirator:

(A) The type

and weight of the respirator to be used by the employee;

(B) The

duration and frequency of respirator use (including use for rescue and escape);

(C) The

expected physical work effort;

(D) Additional

protective clothing and equipment to be worn; and

(E) Temperature

and humidity extremes that may be encountered.

(ii) Any

supplemental information provided previously to the PLHCP regarding an employee

need not be provided for a subsequent medical evaluation if the information and

the PLHCP remain the same.

(iii) The

employer shall provide the PLHCP with a copy of the written respiratory

protection program and a copy of this section.

Note to Paragraph (e)(5)(iii):

When the employer replaces a PLHCP, the employer must ensure that the new PLHCP

obtains this information, either by providing the documents directly to the

PLHCP or having the documents transferred from the former PLHCP to the new

PLHCP. However, OSHA does not expect employers to have employees medically

reevaluated solely because a new PLHCP has been selected.

(6) Medical

determination. In determining the employee's ability to use a respirator, the

employer shall:

(i) Obtain a

written recommendation regarding the employee's ability to use the respirator

from the PLHCP. The recommendation shall provide only the following

information:

(A) Any

limitations on respirator use related to the medical condition of the employee,

or relating to the workplace conditions in which the respirator will be used,

including whether or not the employee is medically able to use the respirator;

(B) The need,

if any, for follow‑up medical evaluations; and

(C) A statement

that the PLHCP has provided the employee with a copy of the PLHCP's written

recommendation.

(ii) If the

respirator is a negative pressure respirator and the PLHCP finds a medical

condition that may place the employee's health at increased risk if the

respirator is used, the employer shall provide a PAPR if the PLHCP's medical

evaluation finds that the employee can use such a respirator; if a subsequent

medical evaluation finds that the employee is medically able to use a negative

pressure respirator, then the employer is no longer required to provide a PAPR.

(7) Additional medical

evaluations. At a minimum, the employer shall provide additional medical

evaluations that comply with the requirements of this section if:

(i) An

employee reports medical signs or symptoms that are related to ability to use a

respirator;

(ii) A PLHCP,

supervisor, or the respirator program administrator informs the employer that

an employee needs to be reevaluated;

(iii)

Information from the respiratory protection program, including observations

made during fit testing and program evaluation, indicates a need for employee

reevaluation; or

(iv) A change

occurs in workplace conditions (e.g., physical work effort, protective

clothing, temperature) that may result in a substantial increase in the

physiological burden placed on an employee.

(f) Fit

testing. This paragraph requires that, before an employee may be required to

use any respirator with a negative or positive pressure tight‑fitting

facepiece, the employee must be fit tested with the same make, model, style,

and size of respirator that will be used. This paragraph specifies the kinds of

fit tests allowed, the procedures for conducting them, and how the results of

the fit tests must be used.

(1) The

employer shall ensure that employees using a tight‑fitting facepiece

respirator pass an appropriate qualitative fit test (QLFT) or quantitative fit

test (QNFT) as stated in this paragraph.

(2) The

employer shall ensure that an employee using a tight‑fitting facepiece

respirator is fit tested prior to initial use of the respirator, whenever a different

respirator facepiece (size, style, model or make) is used, and at least

annually thereafter.

(3) The

employer shall conduct an additional fit test whenever the employee reports, or

the employer, PLHCP, supervisor, or program administrator makes visual

observations of, changes in the employee's physical condition that could affect

respirator fit. Such conditions include, but are not limited to, facial

scarring, dental changes, cosmetic surgery, or an obvious change in body

weight.

(4) If after

passing a QLFT or QNFT, the employee subsequently notifies the employer,

program administrator, supervisor, or PLHCP that the fit of the respirator is

unacceptable, the employee shall be given a reasonable opportunity to select a

different respirator facepiece and to be retested.

(5) The fit

test shall be administered using an OSHA‑accepted QLFT or QNFT protocol.

The OSHA‑accepted QLFT and QNFT protocols and procedures are contained in

Appendix A of this section.

(6) QLFT may

only be used to fit test negative pressure air‑purifying respirators that

must achieve a fit factor of 100 or less.

(7) If the fit

factor, as determined through an OSHA‑accepted QNFT protocol, is equal to

or greater than 100 for tight‑fitting half facepieces, or equal to or

greater than 500 for tight‑fitting full facepieces, the QNFT has been

passed with that respirator.

(8) Fit testing

of tight‑fitting atmosphere‑supplying respirators and tight‑fitting

powered air‑purifying respirators shall be accomplished by performing

quantitative or qualitative fit testing in the negative pressure mode,

regardless of the mode of operation (negative or positive pressure) that is

used for respiratory protection.

(i) Qualitative

fit testing of these respirators shall be accomplished by temporarily converting

the respirator user's actual facepiece into a negative pressure respirator with

appropriate filters, or by using an identical negative pressure air‑purifying

respirator facepiece with the same sealing surfaces as a surrogate for the

atmosphere‑supplying or powered air‑purifying respirator facepiece.

(ii)

Quantitative fit testing of these respirators shall be accomplished by

modifying the facepiece to allow sampling inside the facepiece in the breathing

zone of the user, midway between the nose and mouth. This requirement shall be

accomplished by installing a permanent sampling probe onto a surrogate

facepiece, or by using a sampling adapter designed to temporarily provide a

means of sampling air from inside the facepiece.

(iii) Any

modifications to the respirator facepiece for fit testing shall be completely

removed, and the facepiece restored to NIOSH‑approved configuration,

before that facepiece can be used in the workplace.

(g) Use of

respirators. This paragraph requires employers to establish and implement procedures

for the proper use of respirators. These requirements include prohibiting

conditions that may result in facepiece seal leakage, preventing employees from

removing respirators in hazardous environments, taking actions to ensure continued

effective respirator operation throughout the work shift, and establishing

procedures for the use of respirators in IDLH atmospheres or in interior

structural firefighting situations.

(1) Facepiece

seal protection.

(i) The

employer shall not permit respirators with tight‑fitting facepieces to be

worn by employees who have:

(A) Facial hair

that comes between the sealing surface of the facepiece and the face or that

interferes with valve function; or

(B) Any

condition that interferes with the face‑to‑facepiece seal or valve

function.

(ii) If an

employee wears corrective glasses or goggles or other personal protective

equipment, the employer shall ensure that such equipment is worn in a manner

that does not interfere with the seal of the facepiece to the face of the user.

(iii) For all

tight‑fitting respirators, the employer shall ensure that employees

perform a user seal check each time they put on the respirator using the

procedures in Appendix B‑1 or procedures recommended by the respirator

manufacturer that the employer demonstrates are as effective as those in

Appendix B‑1 of this section.

(2) Continuing

respirator effectiveness.

(i) Appropriate

surveillance shall be maintained of work area conditions and degree of employee

exposure or stress. When there is a change in work area conditions or degree of

employee exposure or stress that may affect respirator effectiveness, the

employer shall reevaluate the continued effectiveness of the respirator.

(ii) The

employer shall ensure that employees leave the respirator use area:

(A) To wash

their faces and respirator facepieces as necessary to prevent eye or skin

irritation associated with respirator use; or

(B) If they

detect vapor or gas breakthrough, changes in breathing resistance, or leakage

of the facepiece; or

(C) To replace

the respirator or the filter, cartridge, or canister elements.

(iii) If the

employee detects vapor or gas breakthrough, changes in breathing resistance, or

leakage of the facepiece, the employer must replace or repair the respirator

before allowing the employee to return to the work area.

(3) Procedures

for IDLH atmospheres. For all IDLH atmospheres, the employer shall ensure that:

(i) One

employee or, when needed, more than one employee is located outside the IDLH

atmosphere;

(ii) Visual,

voice, or signal line communication is maintained between the employee(s) in

the IDLH atmosphere and the employee(s) located outside the IDLH atmosphere;

(iii) The

employee(s) located outside the IDLH atmosphere are trained and equipped to

provide effective emergency rescue;

(iv) The

employer or designee is notified before the employee(s) located outside the

IDLH atmosphere enter the IDLH atmosphere to provide emergency rescue;

(v) The

employer or designee authorized to do so by the employer, once notified,

provides necessary assistance appropriate to the situation;

(vi)

Employee(s) located outside the IDLH atmospheres are equipped with:

(A) Pressure

demand or other positive pressure SCBAs, or a pressure demand or other positive

pressure supplied‑air respirator with auxiliary SCBA; and either

(B) Appropriate

retrieval equipment for removing the employee(s) who enter(s) these hazardous

atmospheres where retrieval equipment would contribute to the rescue of the

employee(s) and would not increase the overall risk resulting from entry; or

(C) Equivalent

means for rescue where retrieval equipment is not required under paragraph

(g)(3)(vi)(B).

(4) Procedures

for interior structural firefighting. In addition to the requirements set forth

under paragraph (g)(3), in interior structural fires, the employer shall ensure

that:

(i) At least

two employees enter the IDLH atmosphere and remain in visual or voice contact

with one another at all times;

(ii) At least

two employees are located outside the IDLH atmosphere; and

(iii) All

employees engaged in interior structural firefighting use SCBAs.

Note 1 to paragraph (g): One of

the two individuals located outside the IDLH atmosphere may be assigned to an

additional role, such as incident commander in charge of the emergency or

safety officer, so long as this individual is able to perform assistance or

rescue activities without jeopardizing the safety or health of any firefighter

working at the incident.

Note 2 to paragraph (g):

Nothing in this section is meant to preclude firefighters from performing

emergency rescue activities before an entire team has assembled.

(h) Maintenance

and care of respirators. This paragraph requires the employer to provide for

the cleaning and disinfecting, storage, inspection, and repair of respirators

used by employees.

(1) Cleaning

and disinfecting. The employer shall provide each respirator user with a

respirator that is clean, sanitary, and in good working order. The employer

shall ensure that respirators are cleaned and disinfected using the procedures

in Appendix B‑2 of this section, or procedures recommended by the

respirator manufacturer, provided that such procedures are of equivalent

effectiveness. The respirators shall be cleaned and disinfected at the

following intervals:

(i) Respirators

issued for the exclusive use of an employee shall be cleaned and disinfected as

often as necessary to be maintained in a sanitary condition;

(ii)

Respirators issued to more than one employee shall be cleaned and disinfected

before being worn by different individuals;

(iii)

Respirators maintained for emergency use shall be cleaned and disinfected after

each use; and

(iv)

Respirators used in fit testing and training shall be cleaned and disinfected

after each use.

(2) Storage.

The employer shall ensure that respirators are stored as follows:

(i) All

respirators shall be stored to protect them from damage, contamination, dust,

sunlight, extreme temperatures, excessive moisture, and damaging chemicals, and

they shall be packed or stored to prevent deformation of the facepiece and

exhalation valve.

(ii) In

addition to the requirements of paragraph (h)(2)(i) of this section, emergency

respirators shall be:

(A) Kept

accessible to the work area;

(B) Stored in

compartments or in covers that are clearly marked as containing emergency

respirators; and

(C) Stored in

accordance with any applicable manufacturer instructions.

(3) Inspection.

(i) The

employer shall ensure that respirators are inspected as follows:

(A) All

respirators used in routine situations shall be inspected before each use and

during cleaning;

(B) All

respirators maintained for use in emergency situations shall be inspected at

least monthly and in accordance with the manufacturer's recommendations, and

shall be checked for proper function before and after each use; and

(C) Emergency

escape‑only respirators shall be inspected before being carried into the

workplace for use.

(ii) The

employer shall ensure that respirator inspections include the following:

(A) A check of

respirator function, tightness of connections, and the condition of the various

parts including, but not limited to, the facepiece, head straps, valves,

connecting tube, and cartridges, canisters or filters; and

(B) A check of

elastomeric parts for pliability and signs of deterioration.

(iii) In

addition to the requirements of paragraphs (h)(3)(i) and (ii) of this section,

self‑contained breathing apparatus shall be inspected monthly. Air and

oxygen cylinders shall be maintained in a fully charged state and shall be

recharged when the pressure falls to 90% of the manufacturer's recommended

pressure level. The employer shall determine that the regulator and warning

devices function properly.

(iv) For

respirators maintained for emergency use, the employer shall:

(A) Certify the

respirator by documenting the date the inspection was performed, the name (or

signature) of the person who made the inspection, the findings, required

remedial action, and a serial number or other means of identifying the

inspected respirator; and

(B) Provide

this information on a tag or label that is attached to the storage compartment

for the respirator, is kept with the respirator, or is included in inspection

reports stored as paper or electronic files. This information shall be

maintained until replaced following a subsequent certification.

(4) Repairs.

The employer shall ensure that respirators that fail an inspection or are

otherwise found to be defective are removed from service, and are discarded or

repaired or adjusted in accordance with the following procedures:

(i) Repairs or

adjustments to respirators are to be made only by persons appropriately trained

to perform such operations and shall use only the respirator manufacturer's

NIOSH‑approved parts designed for the respirator;

(ii) Repairs

shall be made according to the manufacturer's recommendations and

specifications for the type and extent of repairs to be performed; and

(iii) Reducing

and admission valves, regulators, and alarms shall be adjusted or repaired only

by the manufacturer or a technician trained by the manufacturer.

(i) Breathing

air quality and use. This paragraph requires the employer to provide employees

using atmosphere‑supplying respirators (supplied‑air and SCBA) with

breathing gases of high purity.

(1) The

employer shall ensure that compressed air, compressed oxygen, liquid air, and

liquid oxygen used for respiration accords with the following specifications:

(i) Compressed

and liquid oxygen shall meet the United States Pharmacopoeia requirements for

medical or breathing oxygen; and

(ii) Compressed

breathing air shall meet at least the requirements for Grade D breathing air

described in ANSI/Compressed Gas Association Commodity Specification for Air, G‑7.1‑1989,

to include:

(A) Oxygen

content (v/v) of 19.5‑23.5%;

(B)

Hydrocarbon (condensed) content of 5 milligrams per cubic meter of air or less;

(C) Carbon

monoxide (CO) content of 10 ppm or less;

(D) Carbon

dioxide content of 1,000 ppm or less; and

(E) Lack of

noticeable odor.

(2) The

employer shall ensure that compressed oxygen is not used in atmosphere‑supplying

respirators that have previously used compressed air.

(3) The

employer shall ensure that oxygen concentrations greater than 23.5% are used

only in equipment designed for oxygen service or distribution.

(4) The

employer shall ensure that cylinders used to supply breathing air to

respirators meet the following requirements:

(i) Cylinders

are tested and maintained as prescribed in the Shipping Container Specification

Regulations of the Department of Transportation (49 CFR part 173 and part 178);

(ii) Cylinders

of purchased breathing air have a certificate of analysis from the supplier

that the breathing air meets the requirements for Grade D breathing air; and

(iii) The

moisture content in the cylinder does not exceed a dew point of ‑50 deg.F

(‑45.6 deg.C) at 1 atmosphere pressure.

(5) The

employer shall ensure that compressors used to supply breathing air to

respirators are constructed and situated so as to:

(i) Prevent

entry of contaminated air into the air‑supply system;

(ii) Minimize

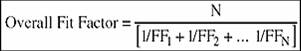

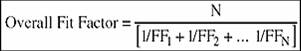

moisture content so that the dew point at 1 atmosphere pressure is 10 degrees F